Combination STRAILway & STRAIL

FACTS

Location: Hódmezövásárhely, Hungary

Client: MÁV AG

Product: STRAILway track sleeper

Length/quantity: 52 sleepers (length from 2,220 mm to 2,240 mm)

Conditions: Rail 54 E1, Fastening SKL-3

Speed 80 km/h, axle load 210 kN

Date: Installation 03/2016 – Inspection 11/2019

ADVANTAGES

- Service life > 50 years

- More robust than wood with similar workability

- Processing without special machines possible

- Less maintenance effort

A QUICK OVERVIEW

In Hungary, wooden sleepers are used as standard in the area of turnouts. At Hódmezövásárhely station the wear and tear of these is however enormous, here a turnout meets a highly frequented level crossing. Therefore a strong alternative had to be found, both for the level crossing and for the sleepers.

The advantages of the STRAILway polymer sleepers convinced MÁV Co. immediately and the planning phase could begin.

At the beginning of 2016, the test installation permit of the state railway was granted and the installation of the STRAILway polymer sleepers started immediately. Due to the easy and quick workability, the sleepers were plated directly on site. After tamping, T-kerbstones were set and a STRAIL level crossing was installed. At the end of 2019, after 3.5 years, no damages or flaws could be detected in the entire area.

Both the sleepers and the level crossing fulfil their purpose to our complete satisfaction.

STRAIL & STRAILway – a powerful combination!

Installation STRAILway polymer sleeper

Installation STRAILway polymer sleeper

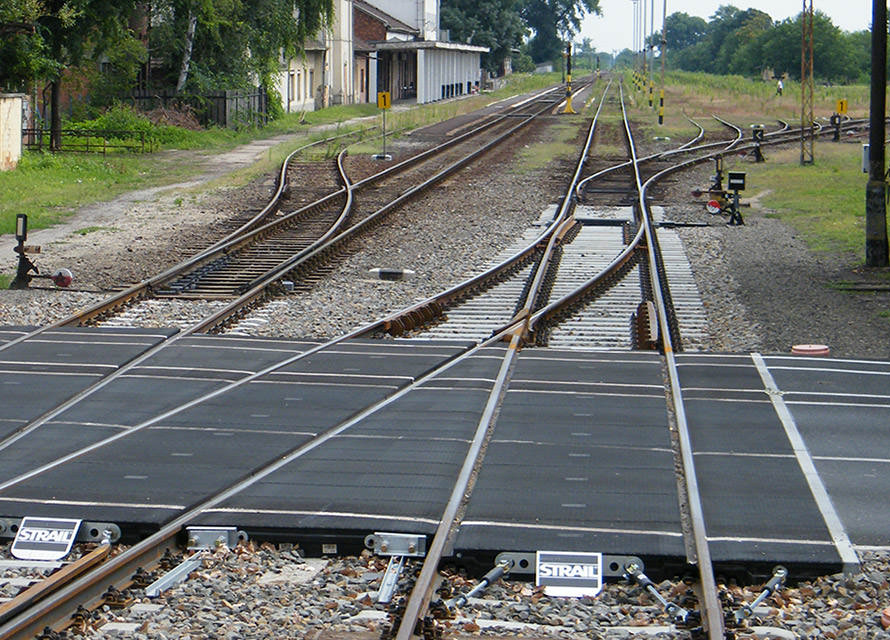

Installation STRAIL level crossing

Installation 2016

Level crossing 2019

Inspection 2019