We are delighted that Quality Austria has renewed the certifications for our quality and environmental management system. We are also now certified for occupational health and safety in accordance with ISO 45001:2018. Together with our existing energy management system, we now have four certified systems.

veloSTRAIL in Fertőszentmiklós, Hungary

FACTS

- Location: Fertőszentmiklós railway station, Hungary

- Track: Sopron-Győr

- Client: GYSEV ZRt.

- Product: veloSTRAIL

- Length: 2 x 4.8 m

- Conditions: Rail MAV 48.5 and UIC 54, Axle load 22.5 t

- Period: July 2022

ADVANTAGES

- Eliminates the flange groove.

- Only system for train speeds up to max. 120 km/h (depending on country of installation).

- Interchangeable elements can be easily exchanged without removing the inner panel.

- No need to keep the flange groove free of dirt, snow and ice.

AT A GLANCE

In 2021, GYSEV ZRt. began modernising Fertőszentmiklós railway station and renovated the station building as a first step. Fertőszentmiklós is an important railway station on the Sopron-Győr line with international connections, for example to Neusiedl am See and Vienna in Austria.

As part of the modernisation of the station, construction of new high platforms began in spring 2022. To provide barrier-free access to the platforms, GYSEV ZRt. opted for the veloSTRAIL level crossing system. veloSTRAIL closes the flange groove and thus makes it safe for pedestrians, cyclists and wheelchair users to cross railway tracks or even for people with pushchairs. Railway traffic is not affected.

Two level crossings at Fertőszentmiklós station have been installed with veloSTRAIL. By the autumn of 2022 all construction work relating to the renewal of the high platforms was completed.

The platforms can now be reached safely thanks to veloSTRAIL and have new rain protection devices and a modern passenger information system.

Image 1: With veloSTRAIL, access to the new high platforms at Fertőszentmiklós station is safe and barrier-free.

Image 2: veloSTRAIL closes the flange groove and thus makes crossing railway tracks safe for pedestrians, cyclists and wheelchair users or even for people with pushchairs. Railway traffic is not affected.

Image 3: Completed level crossings with closed flange groove.

72 m long veloSTRAIL level crossing in Preston (UK)

FACTS

- Location: Preston, North West England (UK)

- Line: Ribble Railway, Strand Road

- Client: Ribble Rail

- Products: 72 metres veloSTRAIL inner panels, STRAIL outer panels, T-kerbstones

- Conditions: G44-sleepers, BS113A rails, radius 169 m

- Period: March 2022

AT A GLANCE

Strand Road in Preston is a busy road that connects Preston Station with Preston Docks. The level crossing there was in a very poor condition and was increasingly posing a danger to traffic, particularly for the many cyclists who pass the level crossing every day.

Ribble Rail therefore decided to upgrade the level crossing and the road surface in Strand Road in March 2022. In order to provide a safe and

gap free crossing for cyclists, the company opted for the veloSTRAIL level crossing system.

For the construction work, the entire Strand Road was closed for a month. During this time, workers laid the track and the T-kerbstones.

The existing track components were replaced with G44 sleepers with BS113A rails in a 169 m radius.

For additional stability, the sleepers were cemented in place. The installation of veloSTRAIL went smoothly and took only five hours despite

the 72-metre length of the level crossing.

Rerailing platform on high speed line

FACTS

- Location: Marseille (FR)

- Line: LGV (Ligne à Grande Vitesse) Sud-Est, North tunnel entrance

- Client: SNCF RESEAU

- Products: innoSTRAIL, supports panel, adjusted panel, removable panel and special concrete kerbstone

- Lenght: Rerailing platform 2 x 19,80 ML – approx. 140 m²

- Axle load: 17 t

- Speed: max. 270 km/h

- Conditions: Rail 60E1, sleepersSATEBA/SNCF VSBGV, Fasting NABLA/STEDEF and NABLA/FBM99

- Period: December 2022 and March 2023

ADVANTAGES

- Patented high-tech rubber surface with vulcanized corundum ensures excellent slip resistance

- Perfect system for starting points for maintenance and rescue vehicles as well as for level crossings with medium to high load

- Adapted design for the LGV high-speed line (270 km/h)

- Easy removal and maintenance due to removable plates

- Long service life

AT A GLANCE

23 years ago, the siding platform at the north entrance of the LGV Sud-Est tunnel in Marseille was covered with ecoSTRAIL.

Now this old STRAIL system was to be replaced by new innoSTRAIL panels. The new platform should be homogeneous and flat, optimally integrate the platforms into the level crossing and ensure easy installation and removal for maintenance purposes.

In addition to these features, the challenge was to carry out the entire installation during the night. There was only a time window of two hours available per night. Every morning, the area had to be accessible again for possible fire brigade operations.

The new platform, which extends over two tracks with a length of 19.80 m and covers an area of around 140 m², was covered with the innoSTRAIL system, which is independent of sleeper pitch.

Modified rubber panels were placed between the struts and blocks of the BI-Block sleepers to compensate for height differences.

Customised outer panels with superelevation allow vehicle access to the platform. The decking was divided into three “zones” to allow for quick replacement of panels.

The STRAIL team developed inspection hatches in addition to the finishing slabs to facilitate access to the electrical boxes on the fixed guideway.

In addition, individual kerbs with integrated pressurised water pipes were laid to ensure a water supply to the tunnel during fire brigade operations.

The installation lasted a total of 16 nights with road closures of two to three and a half hours per night. The project was successfully implemented and met all SNCF RESEAU requirements.

Picture 1: Installation of an removable module.

Picture 2: Installation of an outer panel.

Picture 3: Installation of the individual kerbs with integrated pressurised water pipes.

Turnout sleepers in a steelwork in Salzgitter

FACTS

- Location: Steelwork Salzgitter, Deutschland

- Client: Verkehrsbetriebe Peine-Salzgitter GmbH

- Products: STRAILway turnout slepper

- Length/Quantity: 89,3 running metres /20 pieces

- max. Axle load: 37,5 t

- max. Speed: 25 km/h

- Conditions: Rail 54E4

- Period: May 2018

ADVANTAGES

- Service life > 50 years

- Particularly resistant to all environmental influences

- Suitable for heavy loads

- No working in of the ribbed plate

- No stripping of screw heads

- Excellent screw extraction force

AT A GLANCE

Salzgitter Flachstahl GmbH, a subsidiary of the Salzgitter Group, was looking for new sleepers for the works railway between the blast furnace and the rolling mill. Around 15 million gross tonnes of load roll over this track, including the turnouts, every year.

Previously, wooden sleepers were used, but they had to be replaced every five to seven years. The requirements for the new sleepers were therefore primarily: easy maintenance, durable, suitable for heavy loads.

The decision was made in favour of the STRAILway polymer sleeper, as it meets all the requirements and also provides an all-round carefree package, so to speak.

It is not necessary to work gravel and the ribbed plate into the STRAILway polymer sleeper, screws do not have to be retightened, and should a screw break off in exceptional cases, the sleeper can be repaired and does not have to be replaced.

The STRAILway polymer sleepers at the Salzgitter steelworks have been in use since 2018 and are still as good as new.

Picture 1: Since 2018, the STRAILway polymer sleepers have been in use at the steelworks in Salzgitter.

Picture 2: The durable STRAILway polymer sleepers are ideally suited for heavy-duty turnouts and are maintenance-free.

Picture 3: Prefabricated heavy-duty turnout with STRAILway polymer sleepers.

innoSTRAIL with connection plate

FACTS

- Location: Nieuwegein, Netherlands

- Client: Bestuurs Regio Utrecht (BRU)

- Products: innoSTRAIL, connection plates

- Length: 10 x innoSTRAIL in total 115,2 m

- Conditions: Rail: 49E1, sleeper: B70 and concrete flat, radius 40 m

- Period: in phases from 2017 to 2019

ADVANTAGES innoSTRAIL

- Suitable for level crossings with medium to high loads

- Independent of slepper spacing

- Individually adaptable to almost all requirements and climates

- Fast, simple installation and removal

- Long service life

ADVANTAGES CONNECTION PLATE

- Seamless connection to concrete surfaces

AT A GLANCE

The operator of Sneltram (city railway) around Utrecht, Bestuurs Regio Utrecht (BRU), needed a new workshop and a siding area for new vehicles.

Due to the long-standing and good cooperation with KRAIBURG STRAIL and Nedstrail, as well as the high-quality products from STRAIL, BRU decided to work together again. The level crossing system innoSTRAIL and specially designed connection plates from STRAIL were used.

The level crossing panels were directly connected to the hall and run in a tight radius. The connecting plates ensure a seamless transition between the level crossing and the hall. The plates were anchored directly into the concrete hall floor with heavy-duty dowels. This allowed the inner and outer panels to be bolted to the hall floor.

The installation of the level crossing plates started at the connecting plate and not, as usual, in the middle of the level crossing.

Picture 1: BRU relied on STRAIL products for the construction of a new workshop and sidings.

Picture 2: Using specially designed connection plates from STRAIL, the inner and outer panels were seamlessly screwed to the hall floor.

Picture 3: The installation of the level crossing began at the connection plate and not, as usual, in the in the middle of the level crossing.

pedeSTRAIL with drainage kerbstone

FACTS

- Location: Railway station Nuth, Netherlands

- Line: Schinnen – Heerlen, stop Nuth

- Client: Bouwplaats de Wilde Spoorbouw

- Products: pedeSTRAIL with drainage erbstone

- Length: 4,5 meters

- Conditions: UIC54 / NS90

- Period: August 2021

ADVANTAGES Drainage kerbstone

- Identical in design with T-kerb with an integrated drainage system.

- The surface water of the road is kept away from the level crossing and can seep into the ground.

- Quick installation in combination with standard foundations from STRAIL.

AT A GLANCE

At the railway station in Nuth, located in the hilly and rainy province of Limburg, well-functioning drainage has always been an important issue. That is why the STRAIL drainage kerbstone was added to the pedeSTRAIL system, which is used very frequently in the Netherlands. The D-kerbstone could be added to the existing drainage system without any problems.

With the pedeSTRAIL level crossing system and the STRAIL drainage kerbstone, a safe, barrier-free and dry crossing of the tracks in Nuth is now possible.

Picture 1: The drainage kerbstone is easy to connect to the existing drainage system.

Picture 2: The drainage kerbstone can be combined with all STRAIL level crossings.

Picture 3: The drainage kerbstone keeps the surface water of the road away from the level crossing, so it can seep into the ground.

veloSTRAIL in Bergen (Germany)

FACTS

- Location: Bergen, Deutschland

- Line: Celle – Beckedorf, Bahnübergang Huxahl

- Client: Schieneninfrastruktur Ost-Niedersachsen GmbH

- Products: veloSTRAIL

- Length/Quantity: 56,4 Metres

- Conditions: rail S49, sleeper B70w, radius 300 m

- Period: April 2020

ADVANTAGES

- Eliminates the flange groove.

- Only system for train speeds up to max. 120 km/h (depending on installation country).

- Interchangeable flangeway element can be easily replaced without removing the inner plate.

- No need to keep the flange groove free of dirt, snow and ice.

AT A GLANCE

Level crossings with acute crossing angles are always a danger, especially for vehicles with narrow wheels such as bicycles or motorbikes. When passing the level crossing, the narrow tyres can get caught in the flangeway. A serious fall can be the result.

In Bergen, in the Huxahl area, there is a level crossing with a particularly acute crossing angle. In order to avoid accidents with two-wheelers here, the railway operator decided to use the barrier-free veloSTRAIL system when renewing the level crossing.

veloSTRAIL closes the flangeway and thus eliminates the risk of accidents. The railway traffic is not affected by this.

The renewal of the level crossing in Huxahl went quickly and smoothly.

Picture 1: The old Huxahl level crossing had a large flangeway and crossed the road at a very acute angle. This made it extremely dangerous for two-wheelers.

Picture 2: Finished level crossing with closed flangeway.

STRAILgrid in Goeteborg-Sävenäs

FACTS

- Location: Göteborg-Sävenäs railway station, Sweden

- Client: Trafikverket

- Products: STRAIlgrid

- Area: 5,4 m x 9 m

- Conditions: Track switch

- Period: March 2017

ADVANTAGES

- Protects against unauthorised access to the track bed

- Adapted to the technical conditions on site

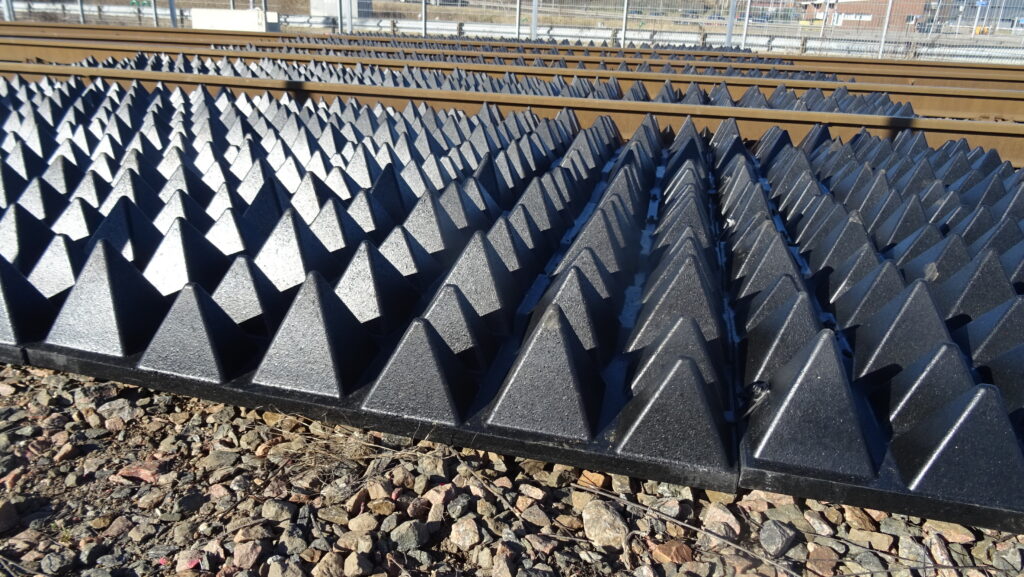

- Irregular pyramid surface > staggered peaks in rows

- Simple and fast installation and removal

- No machine use necessary

AT A GLANCE

At the Gothenburg-Sävenäs locomotive station, people often walked on the tracks, creating extremely dangerous situations. Therefore, the operator decided to erect fences along the tracks and also install STRAILgrid. STRAILgrid is a universal panel that uses an irregular pyramid surface with rows of staggered rubber spikes to prevent passers-by and animals from entering the track area.

During the installation, the construction workers first slightly removed the ballast and then pushed the pre-assembled elements into the sleeper compartments under the rails from both sides in opposite directions. They fixed the intermediate fastening screws supplied with the intermediate elements. Then the STRAILgrid panels were inserted,screwed down and connected with angled panel connectors.

The installation went quickly and smoothly. In the event of a track being worked through, only a few screws need to be loosened, to remove the universal panels and intermediate elements.

Picture 1: STRAILgrid is a universal panel, with an irregular pyramid surface with rows of staggered peaks made of rubber.

Picture 2: During the installation, the intermediate elements were first inserted and screwed in place.

Picture 3: The STRAILgrid universal panels have been specially cut to size and can be easily removed for track reworking.

STRAILastic_IP in Bonassola (IT)

FACTS

- Location: Cinque Terre, Bonassola

- Line: Coastal mountain trail Cinque Terre

- Client: FS – Ferrovie dello Stato Italiane

- Products: STRAILastic_IP, decor panels street side

- Length: approx. 36 meters

- Conditions: R-500, individual railing

- Period: March 2022

ADVANTAGES

- Only approx. 1,300 mm above top of rail

- No visual impact for residents and passengers

- Fast building permission: Installation without foundation

- Short closure times: Simple and quick installation

- No material fatigue due to vibrations

AT A GLANCE

The double-track coastal mountain line in Cinque Terre in Bonassola runs mainly on bridges through lower-lying coastal villages. As there is no spatial separation between the tracks and the villages, the railway noise spreads particularly strongly into those sections of the coast that are funnel-shaped.

The railway operator was therefore looking for a noise barrier that was compact, quick and easy to install and visually blended into the bridge structure of the line.

The decision was made in favour of the infill panel from STRAILastic. The railing infill panels have vulcanised fastening for mounting. This means that the STRAILastic_IP can be easily and quickly mounted on the railings provided. In the construction project in Cinque Terre, the infill panels were attached to the outside of the railings and the outside of the infill panels were equipped with printed panels in concrete look to match the bridges.

In this way, the infill panels blend in perfectly with the landscape and at the same time provide the necessary tranquillity in the coastal villages.

Picture 1: The infill panels from STRAILastic insulate the railway noise along the double-track coastal mountain line in Cinque Terre in Bonassola.

Picture 2: The infill panels have vulcanised fixing for fastening on existing railings.

Picture 3: Because of printable panels, the infill panels can be visually adapted to the surroundings.